Coppabella Township Water Treatment Plant

Customer: Aurizon Holdings Limited

Location: Coppabella, QLD

Case Study ID: CS-37

Date: June 2016

Download PDF Version >>

Overview

Aurizon Holdings Limited have engaged Dowdens Pumping & Water Treatment Mackay & Brisbane Branches to deliver a Water Treatment Plant (WTP) at their Coppabella Township, located on the Goonyella Rail Corridor (the world’s most extensive metallurgical coal rail system) – 159 kilometres South West of Mackay, QLD.

The township of Coppabella was primarily designed and built to service the junction of two railway lines (one from Goonyella Coal Mine and one from Saraji Coal Mine) and to provide accommodation to the region’s coal mine workers in work depots. The town was established in three stages, with the first being completed in 1971, the second in 1977 and the third and final stage in 1984.

The town is wholly owned and operated by Aurizon Holdings Limited. It contains service stations, residences, single-quarters, work depots, hotel, a shop, swimming pool, football oval, caravan park, school, ambulance, fire brigade and of course, the new Dowdens Water Treatment Plant which is capable of producing up to 900kL of potable water per day. Dowdens engineers and service crews designed, manufactured, installed and commissioned the Coppabella WTP to treat raw water to Australian Drinking Water Standards.

The Problem

As the Principal Contractor Dowdens were provided with a set of feed supply water parameters coming into the WTP and water quality requirements to deliver the town’s drinking water. From these basics, the $2.5 million project came to fruition. The Dowdens WTP needed to replace the existing water softening plant (located adjacent to the new WTP) whilst future-proofing the growth of the Coppabella township by increasing the WTP’s maximum daily drinking water production capacity up to 900 kL/day.

Our Solution

Dowdens were successful in the tendering process due to:

- The proximity of Dowdens head office in Mackay and ongoing presence in the region

- Dowdens vast in-house engineering capabilities and proven competencies

- High level of detail provided in the preliminary engineering proposal

- Proposed Water Treatment Plants cost-effectiveness

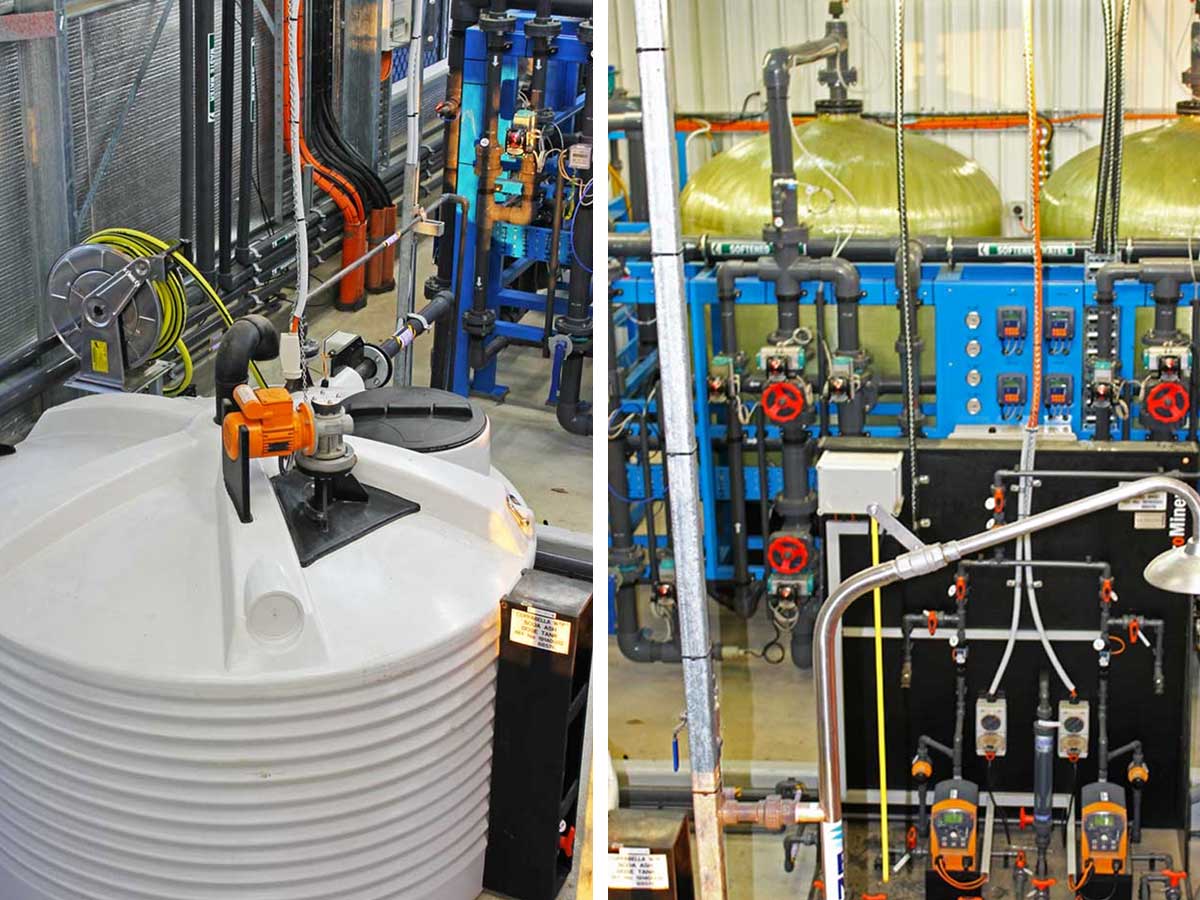

The new WTP is wholly automated and user-adjustable via the GE Human Machine Interface (HMI) situated in the purpose-built site Control Room and Office, minimising the need for direct operator interaction or intervention on-site. A dedicated remote monitoring and alert messaging system was provided so that in the event of a critical alarm the system will call the WTP Operators advising them of the alarm status via pre-recorded spoken messages.

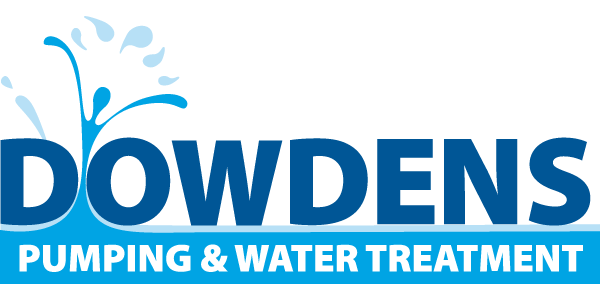

Security of the WTP site was significantly improved with the establishment of a controlled compound restricting access to authorised personnel only. Dowdens also eliminated the need for repetitive manual handling of typical WTP chemical consumables on-site (Salt, Liquid Chlorine and Soda Ash) via the integration of various bulk storage systems.

Dowdens coordinated the design, build and commissioning of the WTP from project inception through to final handover. This included, but was not limited to:

- Preliminary and detailed design;

- Risk assessments (with client and consulting engineers)

- Preliminary civil works establishing the site (levelling site);

- Under boring Peak Downs Highway for installation of raw water pipeline

- Installation of all underground services;

- Pouring of slabs;

- Construction of the Ion Exchange (IX) building;

- Installation of process equipment;

- Installation of all interconnecting pipework;

- Electrical installation of control panel and field instrumentation/equipment;

- Commissioning of instruments / equipment / PLC program and HMI;

- Successful completion of ‘Proof of Performance’ testing and all necessary operator training.

The inclusion of a unique Brine generation system was a novel approach that incorporated a salt bulk bag unloader (capable of lifting 1200 kg bags) and a proprietary self-contained Brine maker. The IX system is flexible in its design and is capable of producing between 150 – 900 kL/day of potable water with the IX system constantly analysing and compensating for variations of incoming bore water hardness levels.

The existing water softening plant (located adjacent to the new WTP) and raw water supply needed to be retained during the new WTP construction. The old plant was decommissioned over a period of 3 months. Nearing project completion, a wet weather event (February 2016) resulted in additional water flows through the WTP site, causing some minor displacement/erosion of soil and stone that required a brief plant shutdown to rectify the damage. Dowdens performed this work efficiently and effectively, eliminating any risk to the township’s drinking water supply.

Key Components

- Control Panel c/w HMI and Remote Monitoring / Automated Alert Messaging System

- Ion Exchange Process used for Bore Water Softening

- Raw and Treated Water Analyser Sampling Systems

- 2 Off Panel Storage Tanks (250kL & 500kL)

- Raw Water Pump Skid

- Brine Generation / Storage System c/w Overhead Bulk Bag Unloader

- Waste Water Distribution System c/w Tank & Pump Set

- Chlorine Dosing Pump / Storage System

- Soda Ash Pump / Storage System

Project Design Philosophy

With a history of successful installations over the past 20 years throughout the Queensland Mining Sector, Dowdens Pumping & Water Treatment can expertly design, manufacture, install and commission specialised pumping and water treatment solutions that are built primarily in-house & onsite to client’s specific unique requirements. The Coppabella WTP Upgrade project is yet another example of Dowdens unparalleled capability to deliver specialised long-term engineered fluid handling solutions from project inception through to final commissioning/handover.

Dowdens Pumping & Water Treatment design philosophy for this project was:

- Cost-Effectiveness

- Innovation and Current Best Practice

- Ease of Installation

- Simple and Effective WTP Operations

- System Reliability & Reduced Ongoing Maintenance