Modular Underground Dewatering System

Customer: BHP Billiton Mitsubishi Alliance (BMA)

Location: Moranbah, QLD

Case Study ID: CS-60

Date: June 2016

Download PDF Version >>

Overview

BHP Billiton Mitsubishi Alliance (BMA) have engaged Dowdens Pumping & Water Treatment’s Mackay Branch to deliver a specialised Modular Underground Dewatering System at their Broadmeadow Coal Mine, located approximately 200 km South-West of Mackay, QLD.

The Broadmeadow Underground Coal Mine is a ‘Top Coal Cave Longwall Punch’ mine located approximately 30 km from Moranbah. Located on BMA’s Goonyella open cut mine lease, the Broadmeadow Mine was established in late 2003 and feature’s BMA’s first application of punch longwall mining — a highly efficient underground technique utilising an existing open cut pit for longwall panel access.

Broadmeadow Mine delivered several synergies between BMA’s underground and open-cut operations, including utilising the existing Goonyella coal preparation plant capacity, increased flexibility to respond to market demand, improved reliability of supply for customers and optimisation of product quality through selective blending.

Dowdens were engaged during the concept phase of this project to provide input and engineering advice to help BMA overcome the many operational challenges this site presented.

The Modular Underground Dewatering System (MUDS) was designed/manufactured and installed by Dowdens Mackay to optimise further development of BMA’s Broadmeadow mining operations by improving on-site dewatering efficiencies. The MUDS have been utilised in developing Broadmeadow panels 12 & 13 and will help to advance mine site progression for the entire life of operations.

Dowdens Pumping & Water Treatment was successful in BMA’s tendering process due to:

- Dowdens In-house engineering, drafting/design, fabrication, servicing capabilities and proven competencies.

- Over 20 years experience designing & producing specialised underground dewatering equipment.

- The proximity of Dowdens head office [Mackay] and ongoing presence in the region Providing a competitively priced solution to the client’s unique challenges.

- High level of detail provided in the preliminary engineering proposal.

The Problem

The main objective of this project was to provide a unique, custom-built air/electric pump system to improve Broadmeadows dewatering efficiency. This was achieved through the automation of pumping systems supplied and lowering any ongoing maintenance requirements — thereby saving site operator input, lowering air/power consumption and reducing the need for BMA to further invest in dewatering pump systems.

Each pump station needed considerable storage/retention capabilities (5,000L per POD) and the capacity to operate seamlessly in sequence, thereby delivering zero overflows onto roadways even during loss of underground power.

The composition of the water derived from the mine’s development process posed its own transportation challenges with a high water content ratio of rock, coal, trash and coal fines. A solids’ management system consisting of various sieves, hoppers and tank agitation components was developed and tested to ensure the coal fines and inflow management system was capable of continuous operation, whilst also delivering simplified maintenance and cleaning procedures.

Our Solution

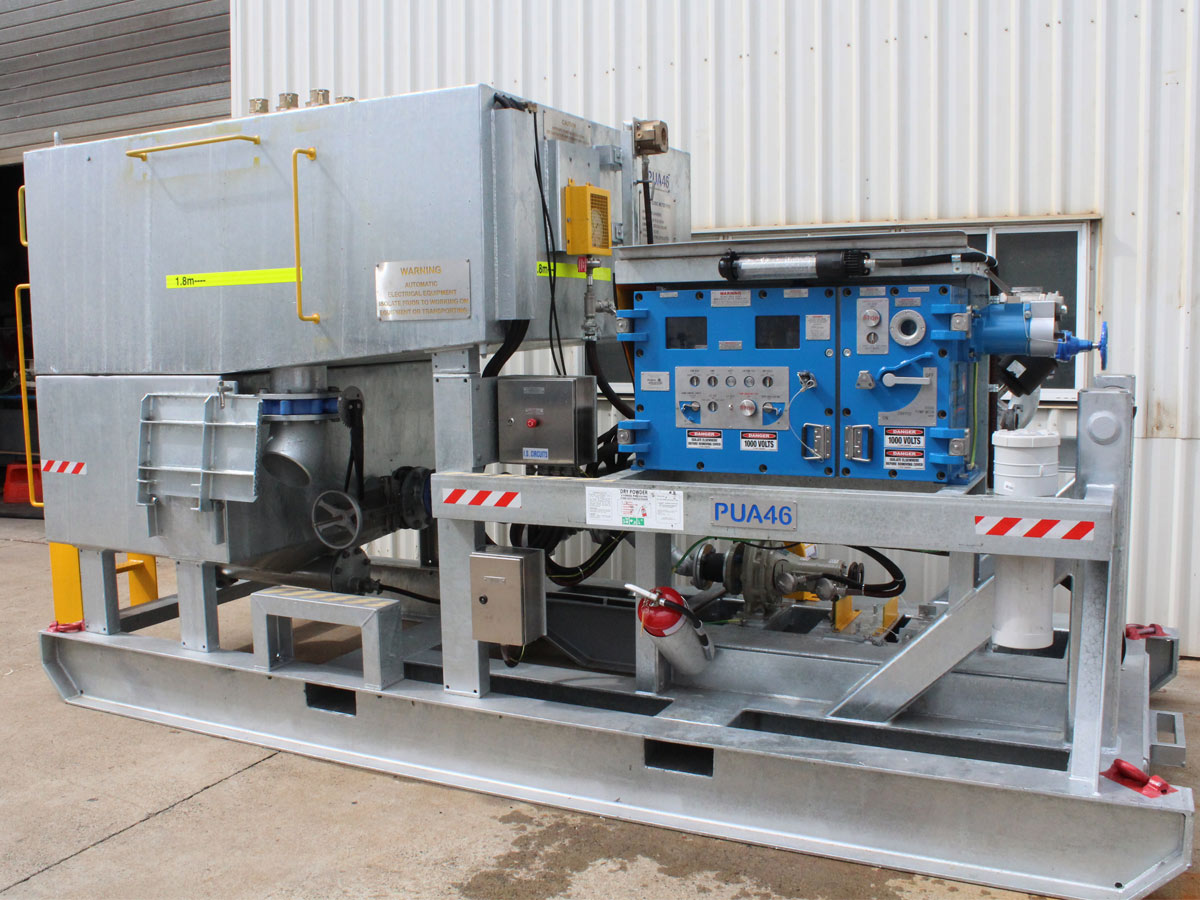

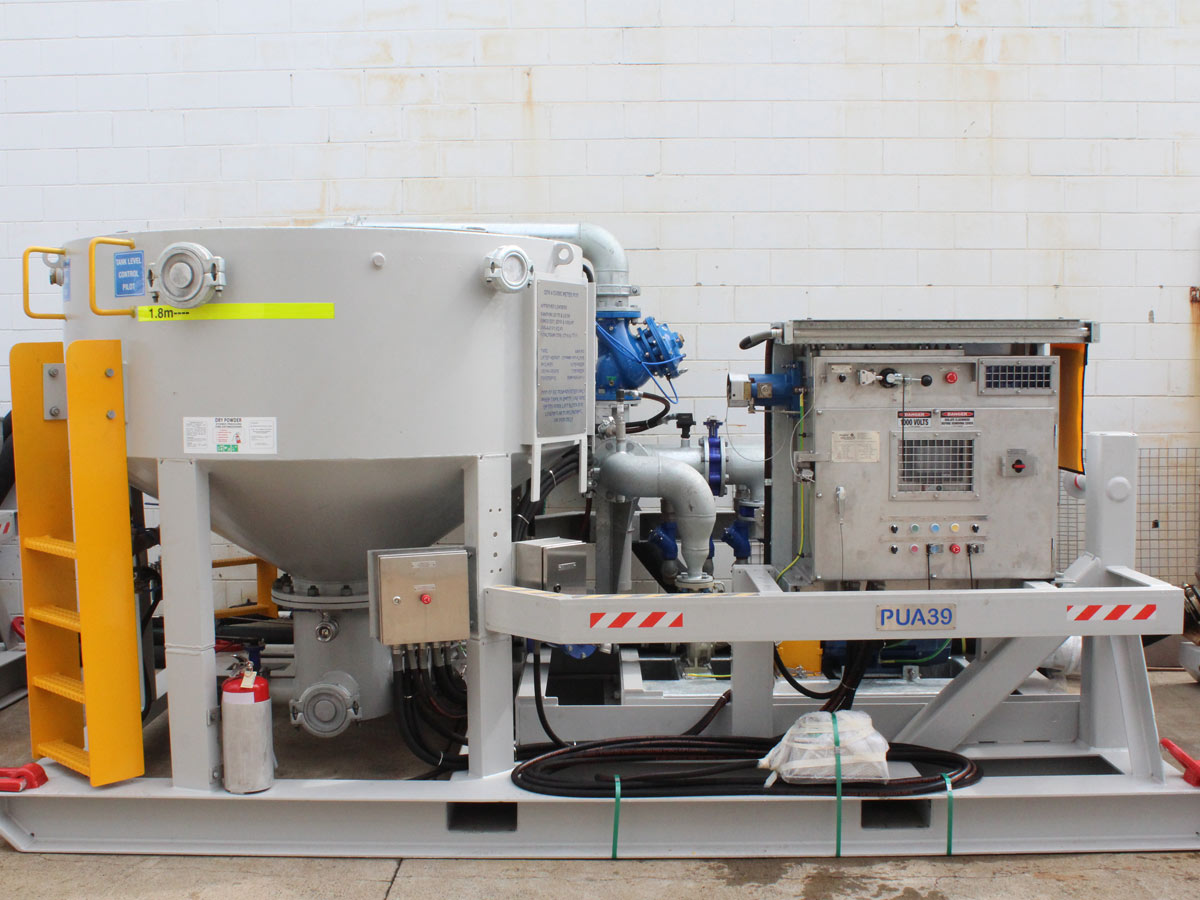

With the negotiations finalised, Dowdens proposed the fabrication of two Teams of 4x Dewatering PODs. Each Team is led by the newly designed 5m³ EXD QDS transportable roadway POD. Three additional specially modified 4m³ Elliptical PODs (a combination of EXD & IP66 rated) are then positioned at strategic intervals along with the panel as main gate development advances.

With intimate product knowledge and via extensive direct consultation, two unique transportable Quick Docking System (QDS) Fish Tank Dewatering POD designs were developed. Capable of operating under 1,000V power, these modular POD systems required the ability to remain operational during regular power outages, utilising the limited underground supply of compressed air.

The coal fines and inflow management system was designed with the ability to:

- Retrofit to existing POD systems recovered from the Crinum underground coal mine

- Bolster the developing site dewatering fleet — with continuity of all pumps, instrumentation & control equipment used.

After a successful tendering process, the Dowdens team of engineers and draftsmen immediately began analysing the recovered Crinum mine 4m³ POD design. After much consideration, a plan was established to incorporate all new specifications and functionality required whilst retaining as much of the existing structure as possible, saving both fabrication time and money. This design was carried over to the new generation 4 m³ Elliptical PODs.

The Narrow Gauge 5m³ Lead POD had to utilise every inch of its restricted underground footprint to facilitate the 5,000L capacity and extra-large solids screening hopper. All work access steps and ladders were designed to be stowed away to avoid contact by passing machinery. All equipment was to be readily accessible to operators, even while positioned hard against the roadway rib. The complete set of design drawings were completed within 5 days, and construction began immediately, ensuring delivery within BMA’s tight project deadlines.

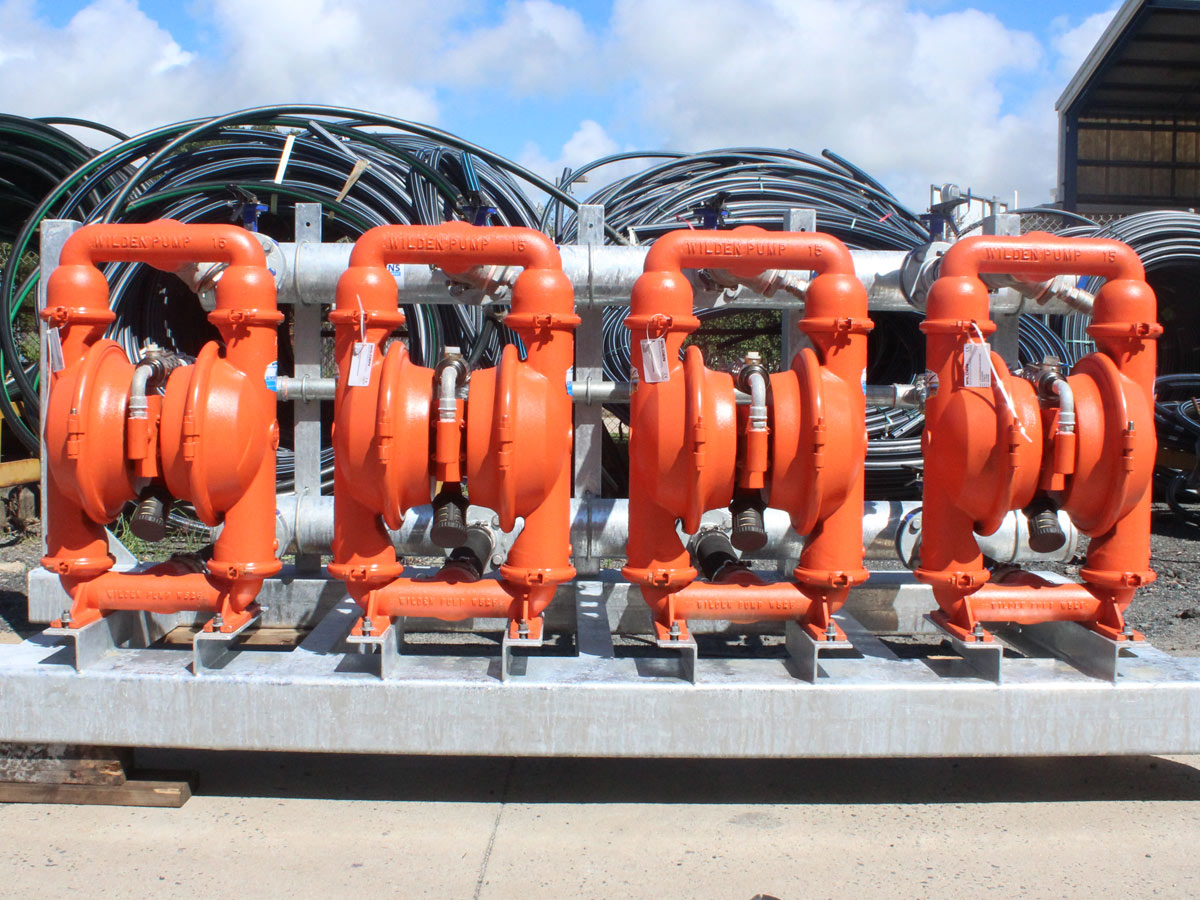

Specially equipped 1,000V electric motors were incorporated in the build to operate custom-made hard-metal centrifugal pumps — primarily selected for water transfer between PODs running in sequence. The Cast Iron WILDEN Air-Operated Double Diaphragm Pump was selected to serve as the auxiliary system for its robustness and relatively small weight-to-flow ratio. The lower weight and lower capital cost of the T15 allowed two pumps to be incorporated into each pump station to serve in duty/standby or duty/assist mode if required.

A pneumatic control system provides seamless switching between air and electric pumping modes. Non-powered level controls allow maximum tank differential between the air pumps ‘on & off’ functions saving air consumption. Potential overflows are prevented by a pneumatically operated, inflow regulating valve. Each of the POD inflow manifolds is equipped with four auxiliary 50 mm pump inputs to integrate localised pumping to the ‘outbye’ system.

Custom-built electrical control panels incorporate all EX’d field devices providing temperature, pressure, flow & fault communications via a PLC to the site Citect system. Area lighting and visual pump status indicator lights can be positioned remotely, ensuring clear viewing from the mines’ underground roadways.

Key Components

- Creation of a completely new Custom Narrow Gauge POD Design to suit clients space restrictions near Development Miner.

- Supply of 2x teams of 4x PODs, 1 team for each main-gate under development (each team consisting of a unique Narrow Gauge 5m³ Lead POD & 3x Modified 4m³ Elliptical PODs)

- Automatic Duty / Standby Cast Iron WILDEN Air-Operated Double Diaphragm Pump Backup with full starting/stopping control to minimise air consumption

- Automatic Shutdown of incoming water on High Tank Level (preventing overflows)

- Two levels of screening for the incoming water to eliminate pump blockages

- Colour Coded POD visual lighting to indicate whether POD is healthy (‘green’) or in fault (‘orange’)

- System designed with site operators needs in mind — No entry to tank required to maintain field devices

- Supply of specially fabricated stainless steel canopies for Pump Starter (top & back) to protect against physical damage

- Provision of DN50 Camlock inlets — providing a readily accessible connection point for incoming water

Project Design Philosophy

Dowdens Pumping & Water Treatment design philosophy for this project was:

- Cost-Effectiveness

- Current Best Practice

- Ease of Installation

- Simple & Effective Plant Operation

- Plant Reliability

- Reduced Ongoing Maintenance