Underground Dewatering PODs

Customer: Anglo American – Grosvenor Coal Mine

Location: Moranbah, QLD

Case Study ID: CS-94

Date: October 2015

Download PDF Version >>

Overview

Anglo American’s Australian Coal division engaged Dowdens Pumping & Water Treatment [Mackay] to deliver eight specialised underground pumping PODs used for various dewatering applications at their Grosvenor Coal Mine, located 190km southwest of Mackay in Moranbah, Central Queensland.

The Grosvenor mine is a developing underground longwall operation that makes up part of Anglo American’s plan to triple hard coking coal production at their Moranbah mine sites. Located next to their existing Moranbah North coal mine, Grosvenor is set to produce up to 5 million tonnes of hard coking coal per annum for export. The Grosvenor mine utilises a 10km overland conveyor to transport high-quality metallurgical coal to the Moranbah North Coal Handling & Preparation Plant.

Construction on Anglo American’s $1.95 billion Grosvenor longwall project began back in January 2013, with the development celebrating a number of industry firsts, including being the first underground coal mine in Queensland to use a tunnel boring machine to develop the drifts, or access tunnels, in coal mine development. Anglo American aimed to have the Grosvenor mine raise the bar for onsite system and production efficiency – making the supply of unique underground POD pumping systems a perfect match for Dowdens Pumping & Water Treatment’s experienced Engineering Department.

The Problem

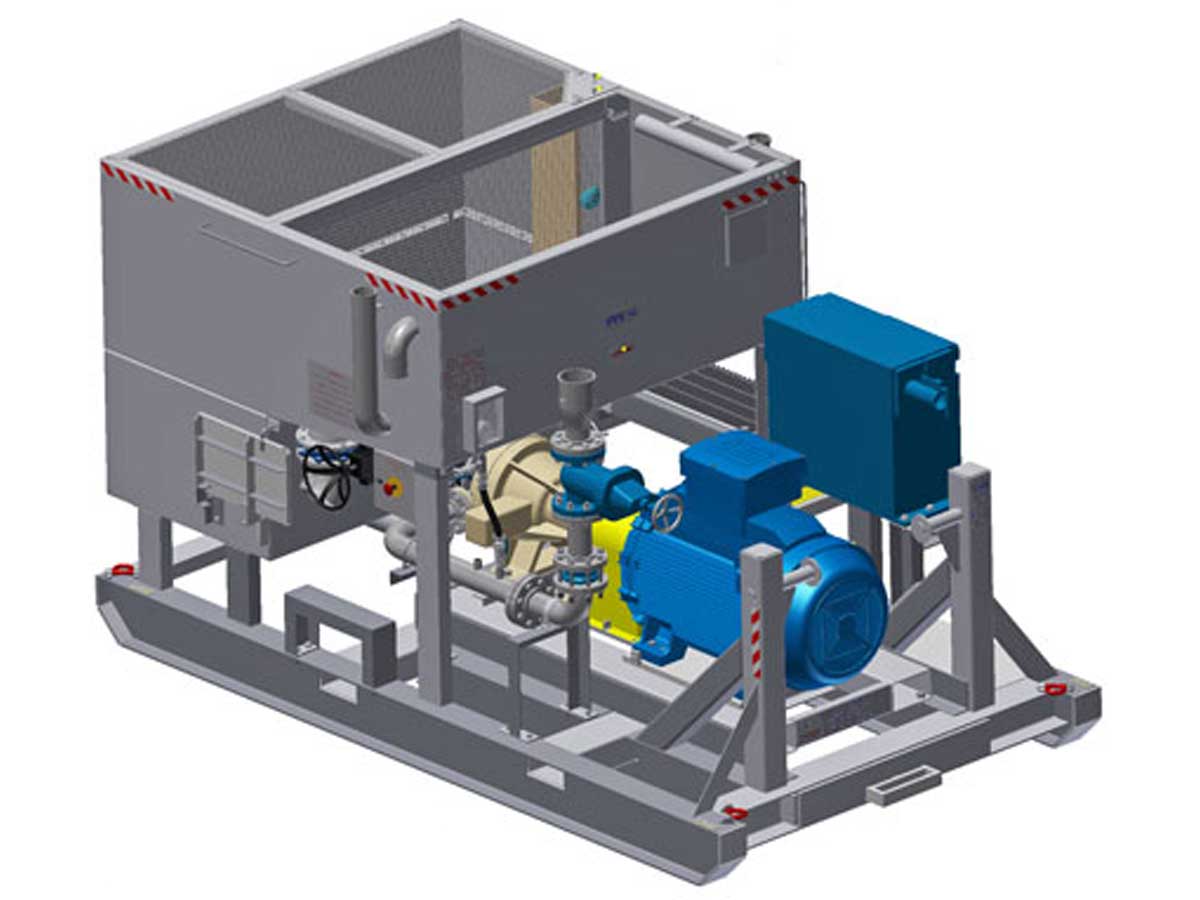

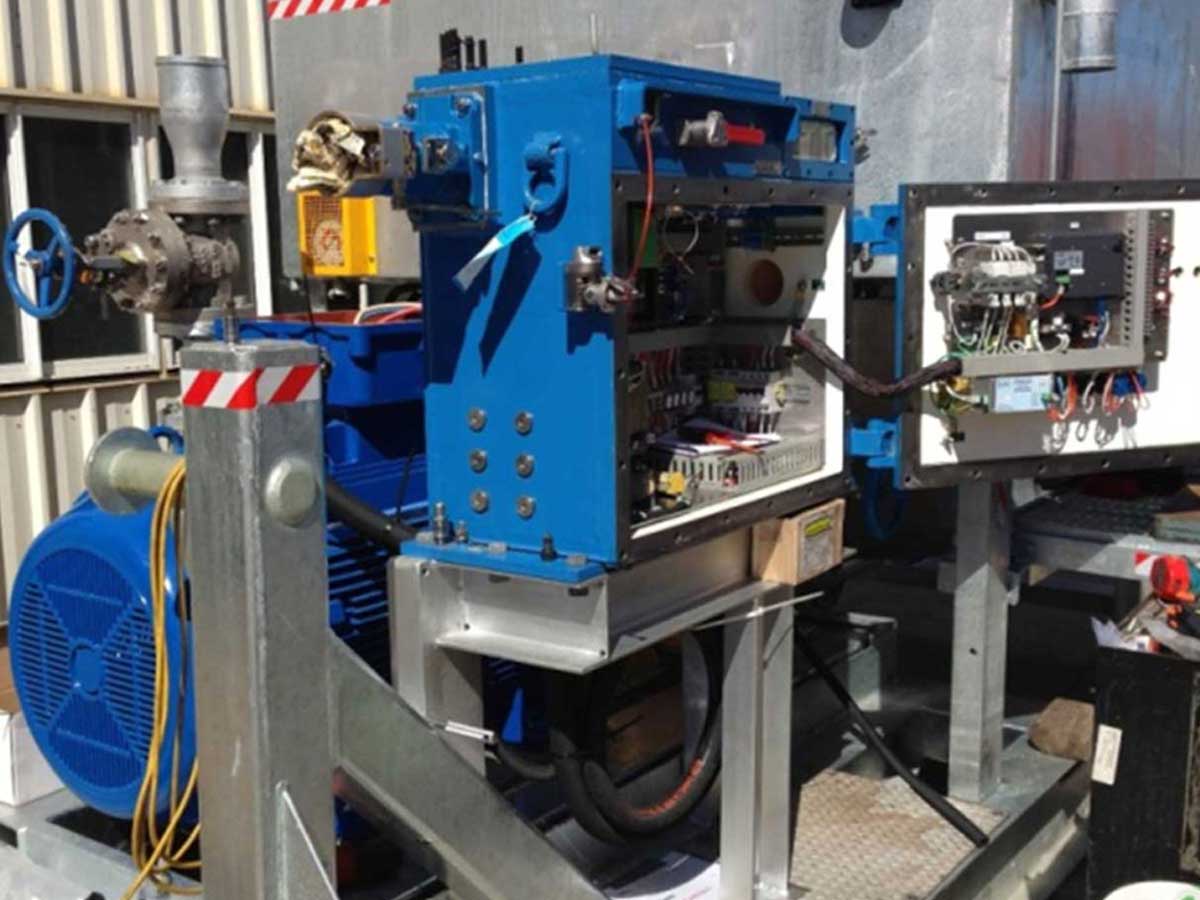

Underground Pumping PODs are used in mines as part of the site water management process. Mining water collected from sumps, and wet areas by Wilden air operated diaphragm pumps (AODP) and delivered to PODs where water level sensors then activate the pump and transfer the collected mine water to a mains pump station, underground storage dam or directly out of the mine portal.

Mining water is typically dirty with coal fine, rocks and dirt; therefore, slurry pumps are required to handle such water. PODs can be located in hazardous areas and can be fitted with Flameproof motors and motor controllers with PLC (Programmable Logic Controllers) and SCADA (Supervisory Control and Data Acquisition).

Please note: The photos may differ from the actual product delivered and are for illustration purposes only.

Our Solution

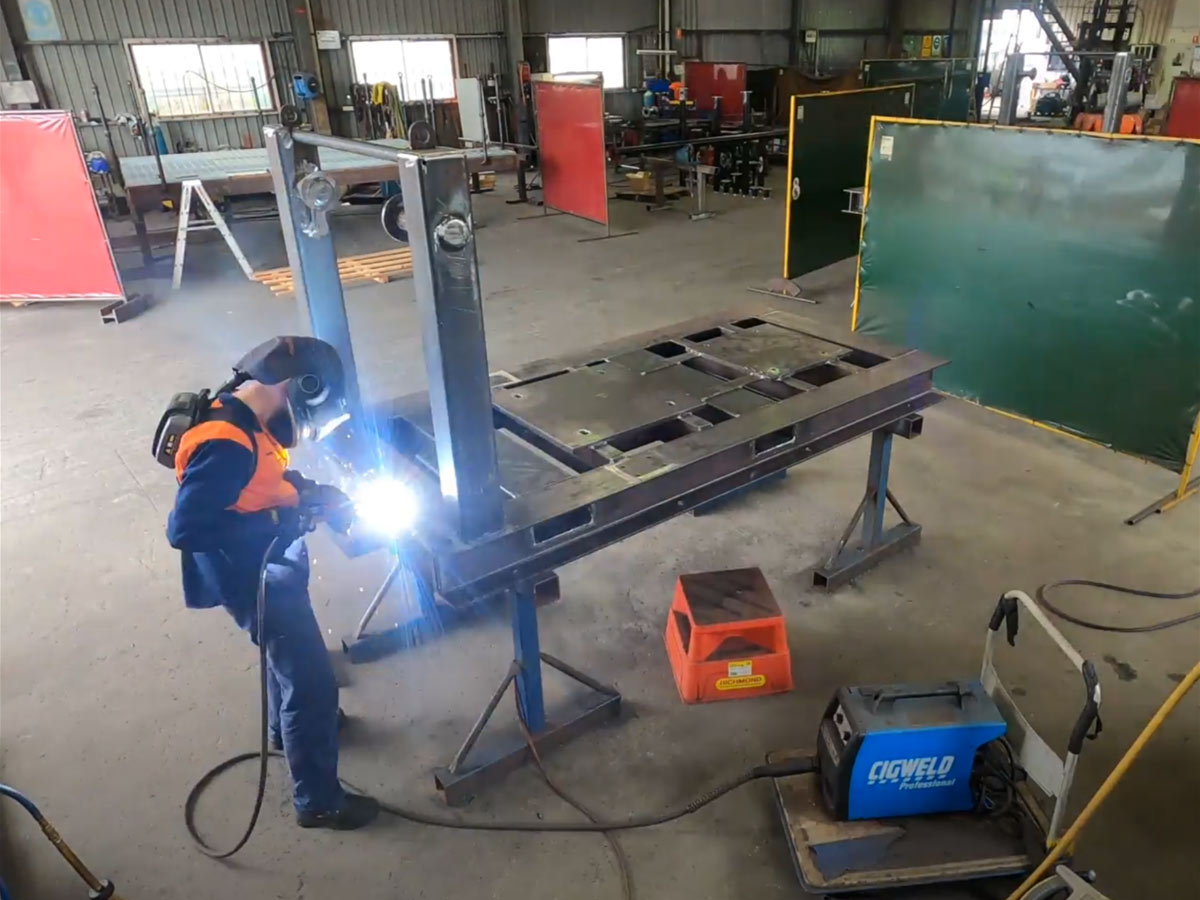

Dowdens Engineering Department’s comprehensive abilities have been on the radar of many Central Queensland/Bowen Basin mines for some time through direct contact and working with industry-leading consulting engineering firms. Dowdens ability to expertly design/manufacture/install, and commission unique equipment built to specific client needs, together with a history of successful installations over the past 15 years in the Bowen Basin, has positioned the business as Queensland’s premier pumping & water treatment organisation.

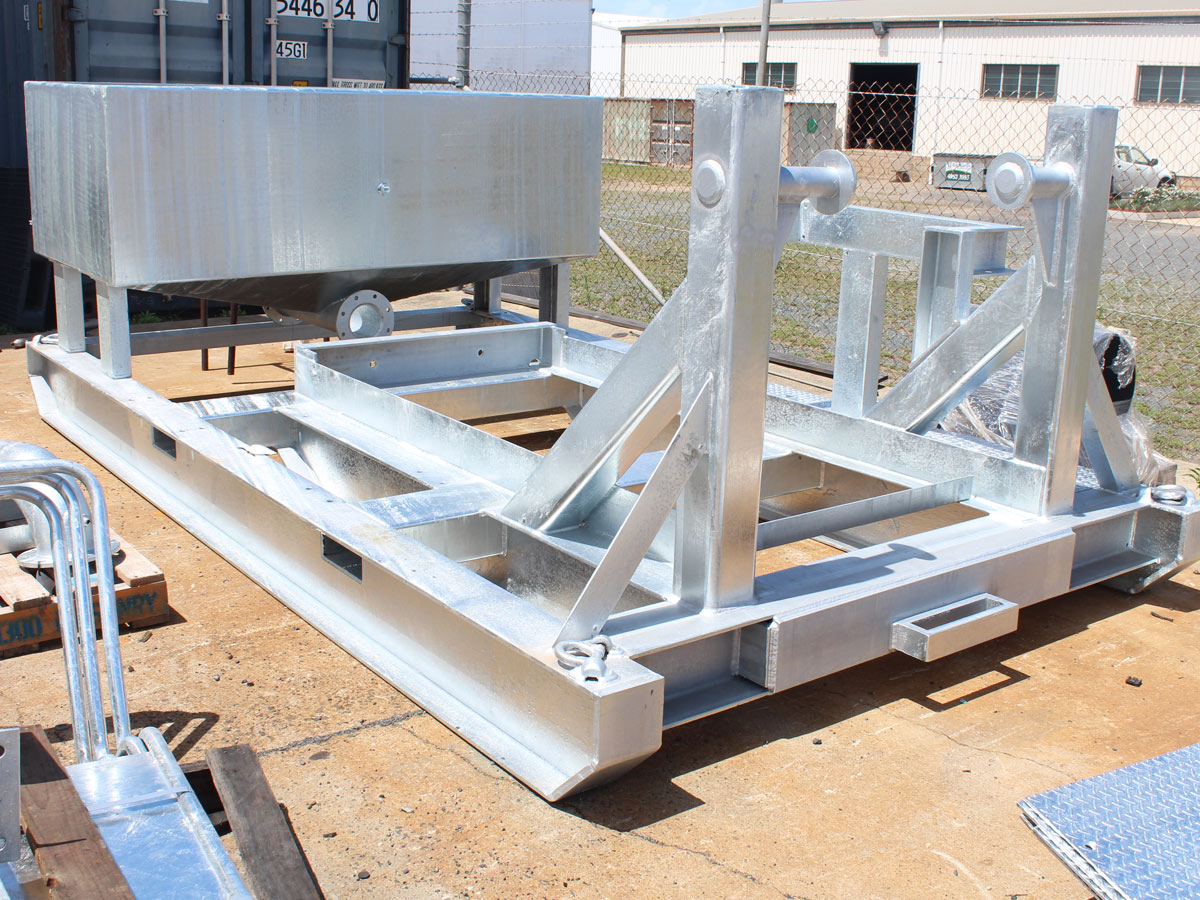

The Grosvenor mine site requirements meant each POD needed to have a 200kW power rating. The site’s physical constraints (i.e. the underground mined roof height and width and the site lifting equipment for transporting) meant careful consideration was required for the overhung load whilst transporting this equipment. The capacity of a standard Dowdens POD is 4m3 with a 110kW motor; however, the more significant flow rate required to and from the POD meant a 6m3 capacity working volume was needed. Bigger capacity and higher duty equated to a larger size motor and pump, more robust steel framework and additional accessibility for scheduled servicing.

Dowdens standard POD design incorporates a dirty water receiving area. This area, integral to the primary hopper (container for a collection of bulk material such as rock or soil), ensures particles that are too large for the pump to digest and transport are separated and manually removed periodically, ensuring trouble-free pumping.

Pumps selected by Dowdens for this harsh duty were Stalker SHD Underground Dewatering pumps with mechanical seals, seal lubrication and cooling. Motors selected were WEG brand Flameproof mine spec motors. The control for the pumps is a flameproof 200kW model with PLC and HMI (Human Machine Interface) screens. The controller starts and stops the pump whilst also monitoring for faults and relaying important information to the mine surface via SCADA. Dowdens PODs built for the Grosvenor mine can easily interchanging the motors/pumps for differing duties. These will be identified as 200kW and 132kW cassettes. The Main Control Unit (MCU) can operate at either 200kW or 132kW with only slight modifications to load controls to accommodate this change.

The larger size and the flexibility to change the duty, together with Dowdens strategic POD site placement advice, has enabled Anglo American less manoeuvring of the POD through development, saving costly underground labour and downtime. Without reliable pumping, the mine’s production slows/halts causing delays and safety issues which cost the mine many thousands of dollars each day. It was imperative the system worked and was highly reliable. This project was delivered on time and within budget. Key project system components are listed below:

Key Features

- Fold-out access platforms for operators to access the instruments and simplify servicing

- Direct fill points to prevent foaming of the mine water

- Overflow points for PODs operation on a steep slope

- Forklift access to both the pump and motor cassette

- The PODs for this mine have the ability of interchangeable motors/pumps for differing duties

- The PODs larger size, flexibility to change their duty, together with Dowdens strategic POD placement advice, enabled Anglo American to save on costly underground labour & pump downtime

- Safety & Design workshop hosted by Dowdens Mackay helped project stakeholders to table all development & maintenance requirements ensuring seamless system delivery

- The project was delivered on time and within budget

Please note: The photos may differ from the actual product delivered and are for illustration purposes only.

Project Design Philosophy

Dowdens Pumping & Water Treatment design philosophy for this project was:

- Cost-Effectiveness

- Current Best Practice

- Ease of Installation

- Simple & Effective Plant Operation

- Plant Reliability

- Reduced Ongoing Maintenance