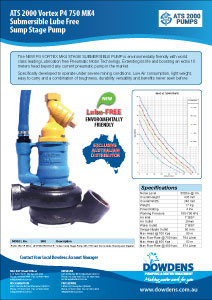

PRODUCT INFORMATION

The new P4 Vortex Submersible Stage Booster Pump Mk4 is environmentally friendly with world-class leading Lubrication free Pneumatic Motor Technology. This technology extends the pump's life and boosts an extra 10 metres of head beyond any current pneumatic pump on the market.

Specifically developed to operate under severe mining conditions. Low air consumption, lightweight, easy to carry, and a combination of toughness, durability, versatility, and benefits never seen before.

SPECIFICATIONS

| Noise Level | 85Dba @ 1m |

| Overall Height |

435 mm |

| Overall Width | 340 mm |

| Weight |

17 Kg |

| Power Rating | 4 Kw |

| Working Pressure |

100-700 kPa |

| Air Inlet |

1” BSP |

| Air Outlet |

25mm |

| Water Outlet |

2” BSP |

| Swage Nipple Outlet |

50 mm |

| Max Head @ 700 Kpa |

80 m |

| Max Flow Rate @ 700 Kpa |

764 L/min |

| Max Head @ 400 Kpa | 53 m |

| Max Flow Rate @ 400 Kpa | 674 L/min |

FEATURES & BENEFITS

| Feature | Benefit | |

| 1 | Pumping Section | |

| 1.1 | Inverted Volute Chamber & Impeller with Side Suction |

Pump is placed on top of dirt, not in it. No need for water filtering screen. What it swallows it will pump. |

| 1.2 | Vortex Pumping | Ability to pump grit, fibers, and small stones, without jamming |

| 1.3 | Inverted Impeller & Volute, are made of SG42 Cast Iron | Allows for flood feed through the sides, no suction required and hard wearing |

| 1.4 | Detachable Impeller cover with “0” ring seal | Three 17mm bolts remove “O” ring cover gaining quick access to the impeller for cleaning. |

| 1.5 | Optional High Volume non-return valve | Helps to keep dirt out of the pump when it stops pumping. |

| 1.6 | Ability to lift the pump out of the water while running. | Pump will maintain water pressure when lifted out of the water allowing transfer to the pump position with little back flow |

| 2 | Motor Section | |

| 2.1 | Environmentally Friendly Lubrication-free motor. |

Motor can be run continuously without oil, eliminating environmental oil pollution, and has an extended motor life. |

| 2.2 | Stainless steel Cylinder and hardened & Rust-free motor parts | Rust-free and highly wear-resistant. |

| 2.3 | An Inverted Impeller allows no high-pressure water on the spindle seals. | Spindle seals control low exhaust air pressure in the motor housing from entering the pump volute. There is no high-pressure water being controlled. |

| 2.4 | Ability to run continuously out of the water. | Motor housing seal is cooled by air passing through the motor into the exhaust. |

| 2.5 | SG42 Cast iron Body | Very tough and durable |

| 2.6 | Ergonomically designed carry handle. | Easy to carry and is also the exhaust housing. |

| 3 | Filter Inlet Section | |

| 3.1 | Built in high capacity in line micro filtering system with flushable and replaceable filter element. | Day-to-day element cleaning is easy and accessible and replacing is via external screw cap. |

| 3.2 | Filter Element | Filter filters out dirt down to 120-micron particles |

LITERATURE AND DRAWINGS

|

ATS450750 Stage brochure |