PRODUCT INFORMATION

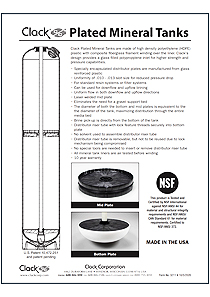

Clack Plated Mineral Tanks

Clack Plated Mineral Tanks are made of high density polyethylene (HDPE) plastic with composite fiberglass filament winding over the liner. Clack's design provides a glass filled polypropylene inlet for higher strength and pressure capabilities.

FEATURES & BENEFITS

- Specially encapsulated distributor plates are manufactured from glass-reinforced plastic

- Uniformity of .010 - .013 slot size for reduced pressure drop

- For standard resin systems or filter systems

- Can be used for downflow and upflow brining

- Uniform flow in both downflow and upflow directions

- Laser welded mid plate

- Eliminates the need for a gravel support bed

- The diameter of both the bottom and mid plates is equivalent to the the diameter of the tank, maximizing distribution through the entire media bed

- Brine pick-up is directly from the bottom of the tank

- Distributor riser tube with lock feature threads securely into bottom plate

- No solvent used to assemble distributor riser tube

- Distributor riser tube is removable, but not to be reused due to lock mechanism being compromised

- No special tools are needed to insert or remove distributor riser tube

- All mineral tank liners are air tested before winding

- 10 year warranty

LITERATURE

|

Clack Dome Hole Tanks Brochure |