PRODUCT INFORMATION

VORTEX SUMP PUMPS

A Davey all-rounder, the General Purpose Vortex Sump Pumps are able to pump clean or grey water of neutral pH, with some soft or fine solids.

Suitable applications include sump emptying, septic effluent disposal, water transfer or pumping of light slurries and factory waste.

Submersible Drainage Pumps

Model Numbers:

- D15VA

- D15VAGMA

- D25VA

- D40VA

APPLICATION

- Firefighting

- Tank filling

- Irrigation

- Garden watering

- Water transfer

- Crop spraying

FEATURES & BENEFITS

WHY CHOOSE DAVEY SUBMERSIBLE DRAINAGE PUMPS?

Semi vortex, open impeller, centrifugal design

- Able to pump soft solids in suspension

- Less susceptible to blockage

D15VA and D15VAGMA models feature a special recirculation port to keep soft solids agitated in sump, improving ability to pump away such solids.

Double mechanical shaft seal in oil bath with hard faced silicon carbide/ceramic seal on pump side (D15VA and D15VAGMA models have single seals).

- Added motor protection

- Long service life

Sand slinger lip seal

- Added protection

- Long service life

Corrosion resistant 304 stainless steel motor shell, shaft, strainer and fasteners with a high quality paint finish.

- Long service life

- Attractive, lasting appearance

Automatic resetting thermal overload.

- Protected against overloading

HO7RNF oil resistant leads, 10 metres long with 3 pin power plug.

- Easy to connect to power supply

- Longer life in dirty water

TECHNICAL DATA

MATERIALS OF CONSTRUCTION

| PART | MATERIAL |

| Impeller | Polycarbonate |

| Pump casing | Cast iron (D15VA & D15VAGMA -glass filled polycarbonate) |

| Mechanical seal (pump end) | Silicon carbide / ceramic oil in bath |

| Mechanical seal (motor end D25VA & D40VA) | Carbon / ceramic |

| Shaft seal elastomer | Nitrile rubber |

| Pump shaft | 304 stainless steel |

| O-rings | Nitrile rubber |

| Motor shell | 304 stainless steel |

| Handle | 304 stainless steel |

| Fasteners | 304 stainless steel |

| Float & power supply leads | HO7RN-F oil resistant |

OPERATING LIMITS

| D15VA D15VAGMA | A D25VA | D40VA | |

| Capacities | 140 lpm | 200 lpm | 240 lpm |

| Heads to | 7m | 6.5m | 7.5m |

| Maximum submergence | 12m | 12m | 12m |

| Maximum operating temperature | 50ºC | 50ºC | 50ºC |

| Maximum soft solids | 20mm O.D. | 25mm O.D. | 35mm O.D |

ELECTRICAL DATA

| Model | Output (watts)* | Start (Amps) | Run (Amps) |

| D15VA | 150 | 9.0 | 1.5 |

| D15VAGMA | 150 | 9.0 | 1.5 |

| D25VA | 250 | 12.0 | 2.0 |

| D40VA | 400 | 10.5 | 3.7 |

D15VAGMA FLOAT CUT-IN & CUT-OUT LEVELS

| Pump Start | 230mm above base |

| Pump Stop | 140mm above base |

INSTALLATION & PRIMING

Use a rope to position and retrieve the pump. Do not lower or retrieve the pump using the power lead as this may damage the cable entry seals, causing water leaks and unsafe operation.

Don’t use this product for recirculating or filtering swimming pools, spas, etc.

While these pumps are built to high safety standards, they are not approved for installations where people will be in the water while they are operating.

Don’t pump abrasive materials. Sand and grit in the water being pumped will accelerate wear, causing shortened pump life.

Make room for the float switch to operate. Automatic models have a float switch to turn them on when the water level rises and turn them off again when it has been pumped down to the safe operating level of the pump. If the float switch is not free to rise and fall, correct pump operation may not be possible.

Don’t run your pump dry.

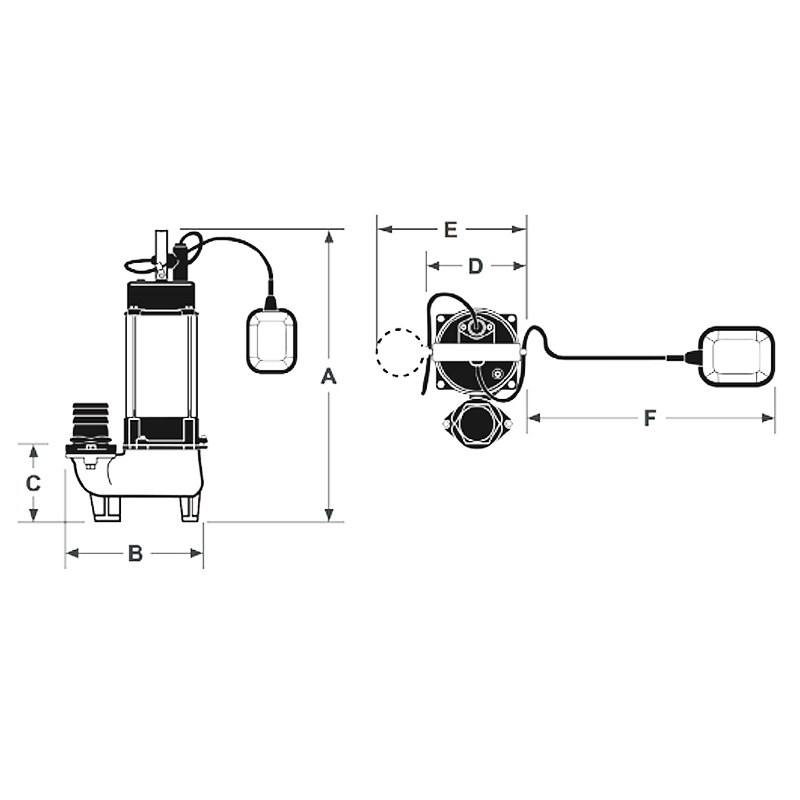

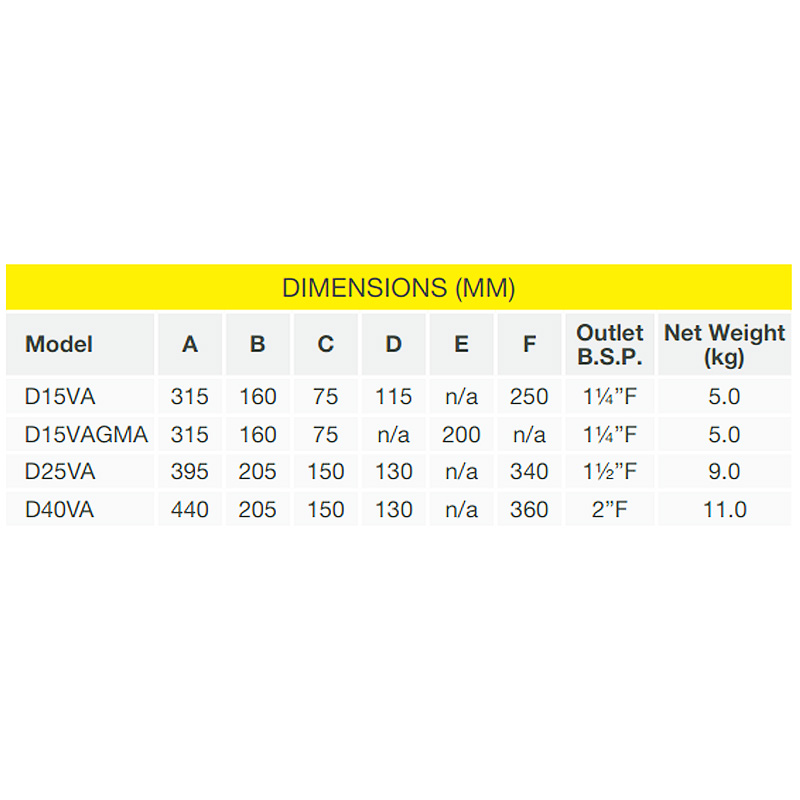

DRAWINGS

|

|

LITERATURE

|

Davey D15VA Submersible Drainage Pumps Brochure |