PRODUCT HELP

Below are two guides to help you with product selection; temperature limits and a chemical guide. For further information please check features and specifications.

TEMPERATURE LIMITS

Please Note: It is IMPORTANT to also read Section 1 of the applicable Wilden Brochure which explains Pump and Diaphragm temperature limits. This will help you with selecting the correct pump for you application.

| Diaphragm Material

|

Temperature Limit

|

| Acetal

|

29°C to 82°C

|

| Buna-N

|

12°C to 82°C

|

| Geolast®

|

40°C to 82°C

|

| Neoprene

|

18°C to 93°C

|

| Nordel® EPDM

|

51°C to 138°C

|

| Nylon

|

18°C to 93°C

|

| PFA

|

7°C to 107°C

|

| Polypropylene

|

0°C to 79°C

|

| Polyurethane

|

12°C to 66°C

|

| PVDF

|

12°C to 107°C

|

| PTFE

|

4°C to 104°C

|

| PTFE with EPDM-backed

|

4°C to 137°C

|

| PTFE with Neoprene-backed

|

4°C to 93°C

|

| Saniflex

|

29°C to 104°C

|

| Viton® FKM

|

40°C to 177°C

|

| Wil-Flex (Santoprene)

|

40°C to 107°C

|

CHEMICAL GUIDE

| The Wilden chemical resistance guide is compiled from numerous reliable sources and cross-checked; however, it is only intended as an additional source of information. Diaphragm life not only depends on a diaphragms chemical compatibility with the process fluid but also on the process conditions. These conditions will vary depending on the abrasiveness of your process fluid, temperature, size of diaphragm, pumping media and lift conditions. Consult your authorized Wilden distributor regarding which diaphragm material will work best for your application requirements.

|

|

PRODUCT INFORMATION

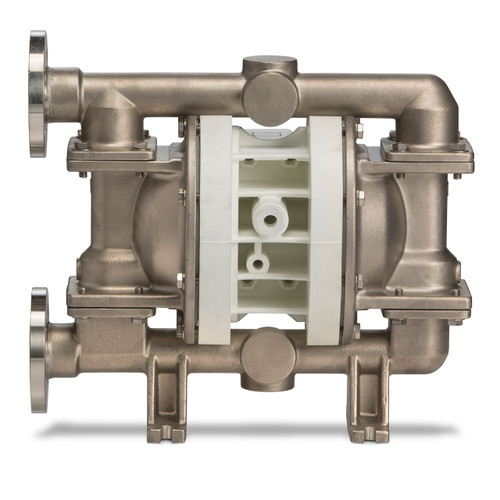

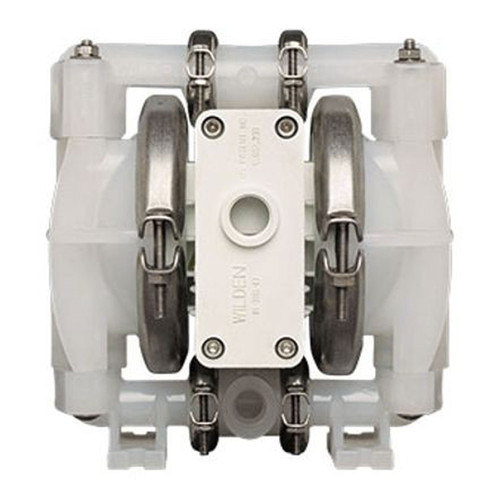

As part of the Wilden® Pro-Flo® Series of AODD pumps, this pump has been specifically designed to increase productivity while reducing air and energy consumption. It utilizes a bolted design for superior product containment in many applications, especially for dangerous or valuable media. Designed for difficult applications, this pump is perfect for chemical and wastewater applications where flow, efficiency and routine maintenance are required.

CERTIFICATIONS

Wilden Pump & Engineering LLC has met the criteria for placing the CE mark on our product line. On December 3, 1999, Wilden fully self-certified its product line by meeting all the regulations of the Machinery and PED (Pressure Equipment) Directives. Every pump manufactured by Wilden will now receive the CE mark. Each pump box will also include a Safety Supplement manual in the eleven official languages of the European Community.

FEATURES

| FEATURE

|

DESCRIPTION

|

| Robustness

|

Fitted with robust Pro-Flo ADS

|

| Fast Maintenance

|

Bolted construction for superior containment

|

| No Priming

|

Self Priming

|

| Run Dry

|

Dry run without damage

|

| Shearing

|

Shear-sensitive

|

| Longevity

|

Longest Mean Time Between Repair (MTBR)

|

| Temperature Tolerance

|

Superior anti-freezing

|

| Reliability

|

Increased On/Off reliability

|

SPECIFICATIONS

| SPECIFICATION

|

DESCRIPTION

|

| Series

|

Pro-Flo

|

| Model

|

P200

|

| Inlet

|

25mm (1")

|

| Outlet

|

25mm (1")

|

| Air Inlet

|

6mm (0.25")

|

| Material

|

PVDF

|

| Assembly

|

Bolted

|

| Connection Type

|

ANSI

|

| Piston

|

Traditional

|

| Stroke

|

Full Stroke

|

| Max Flow Rate

|

220 lpm (58 gpm)

|

| Wetted Path Material

|

PVDF

|

| Gearing

|

1:1

|

| Max Air Pressure

|

125 psi

|

| Max. Solids Passage

|

4.76 mm (3/16")

|

| Weight

|

15 kg (32 lb)

|

| Size (HxWxD)

|

457 x 434 x 231(mm)

|

Please Note: Specification's are a guild only and may change without notice. Please also read the applicable Wilden Brochure for full specifications. E&OE.

LITERATURE AND DRAWINGS