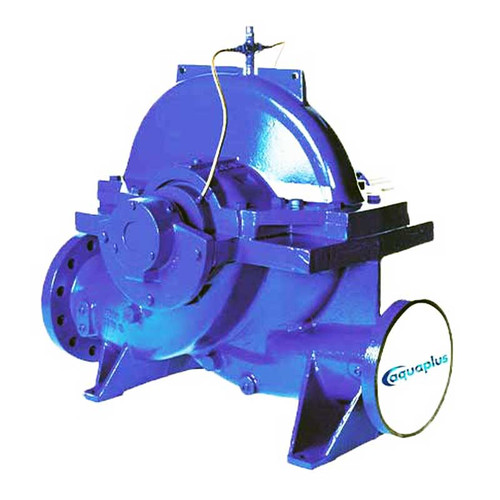

PRODUCT INFORMATION

The Stalker Pumps SHD Series are heavy duty pumps, specifically designed for underground mine dewatering applications the unit can handle aggressive and abrasive liquids while decreasing operational costs and achieving high productivity.What are the advantages of MTP’s Stalker Pumps SHD Series

1. High capacity and better performance

- Can handle abrasive, non-clean fluid with long wear life due to the pumps special design and material options

- Material options include 27pc chrome iron for highly abrasive fluids and H3C stainless steel for highly corrosive and abrasive fluids

- Increased flow rate from 20 to 120 L/s in comparison to 27L/s flow rates of a typical Progressive Cavity Pump

FEATURES

- Suction and Discharge flanges – heavy duty with hole patterns to ANSI Class 150 and 300.

- Major cast components manufactured from heavy section abrasion resistant white iron complying with AS2027.

- Additional components cast from heavy section Spheroidal Graphite (SG) iron complying with AS1831 400 Mpa tensile.

- Impeller material – H3B (AS2074) heat treated stainless steel.

- Shaft material – alloy steel to AS1444-4140 max. 1100 Mpa UTS with O-ring sealed wear sleeve fitted (material AS2837 – 316 stainless steel).

- Mechanical Seal Assembly Cartridge type -heavy duty to suit application.

- Gaskets/Seals/O-rings – insertion rubber/nitrile (viton fluroelastomer option).

- Fasteners – 8.8 grade high tensile Zinc coated and 316 stainless steel.

- Rotating Element Bearings – front angular contact 7316 series & heavy duty ball 6316 (C3) series bearing.

- Rear – heavy duty 6316 (C3) series ball bearing.

- Grease feed with purge flingers.

- Optional builds include compressor assisted pump pre-prime units, base and trailer mounted units.

- Various material options available

APPLICATIONS

- Mine dewatering

- Underground drainage

- Waste water,

- Process water

- Dewatering

- Sewage

- Sea water

- Hazardous or corrosive liquids

LITERATURE AND DRAWINGS

|

Stalker SHD Series Underground Dewatering Pumps Brochure |